Introduction

Welcome to the Stormbird book!

Stormbird is a library for simulating lifting surfaces, e.g., wings, in a simplified way by representing them as line-models. Although this can be used for a variety of different cases, it is mostly developed to offer efficient modeling of modern wind propulsion devices. That is, the following types of lifting surfaces are of particular interest:

- Wing sails

- Rotor sails

- Suction sails

- Kites

To achieve practical modeling capabilities for these use cases, the following physical effects are assumed to be particularly important:

- Various lift generation mechanisms: modern sails have sections that range from classical foils, with and without flaps, rotating cylinders, and foils with boundary layer suction.

- Strong viscous effects: For all lift generating mechanisms above, there will be high lift coefficients with strong viscous effects on both the lift and drag forces. For instance, wing sails tend to be operated close to stall, the lift on a rotating cylinder is strongly affected by partial flow separation, and the lift on a suction sail is very dependent on the amount of boundary layer suction.

- Interaction effects between lifting surfaces: Many wind-powered ships have several sails placed in close proximity. Interaction effects between multiple sails can therefore be important.

- Interaction effects with other structures: Independent of the number of sails, there can be interaction effects between the sails and the rest of the ship, such as structures on deck or the part of the hull that is above the water line.

- Unsteady effects: Ship applications often require modeling of unsteady effects, for instance, to model seakeeping behavior or maneuvering. The sail forces are assumed to be important for such cases, which also introduces dynamic effects on the sails. In addition, kites are often flown dynamically to increase the power extracted from the wind.

At the same time, it is also often necessary that the computations are fast. The user will usually be interested in testing many different weather conditions, ship speeds, sail configurations, and operational variables. The goal is, therefore, to find the right balance between accuracy and speed for the intended use case. To achieve this, the library supports the following methods, that offer different levels of complexity and computational speed:

- Discrete static lifting line, for steady- or quasi-steady cases

- Discrete dynamic lifting line, for unsteady or steady cases with large wake deformations

- Actuator line, for steady and unsteady cases where interaction with other structures is of interest

The library is developed as part of the research project KSP WIND by the Department of Marine Technology at the Norwegian University of Science and Technology. The main developer is Jarle Vinje Kramer.

Who the Book is for

You should read this if you are interested in using Stormbird to run lifting line or actuator line simulations, or if you just want more information on the theory behind each method. The book is intended to introduce the theory, available models, and overall concepts in the implementation. In other words, the goal is to give a bird's-eye view of the library and its functionality. When appropriate, other literature will be referenced for more details. That is, it is written primarily for users, and are therefore not focused directly on the underlying source code. However, there will often be examples from the source code when that is the easiest way to illustrate functionality. For instance, data structures will often be shown directly source code to illustrate what fields and settings that are available.

Don't forget to also look at the code!

The text in this book will not cover everything! It may also, at times, be outdated relative to the latest version of the library. The only way to get a full insight into the inner workings is, therefore, to look at the source code itself and the examples of how to use the code. Below is some relevant links for this purpose

- The Stormbird GitHub page can be found here. It contains the core library, utility functionality, interfaces and examples.

- More specifically, examples of how to use the Python interface of the code can be found here.

- Automated code documentation can be found here for the core Stormbird library and here for the Stormath library, which contains mathematical utility functionality written for Stormbird.

Overview of different versions

Stormbird itself is a Rust library. The Rust programming language was chosen as it combines high computational speed with a modern user-friendly developer experience. One potential way to set up a Stormbird simulation is, therefore, to make a custom Rust executable. However, for those that don't know Rust, or just want to use the library in a high-level setting, it is also possible to use one of the high-level interfaces to the core functionality, listed below:

- The Python interface, implemented in the

pystormbirdmodule. This interface is a direct API to the necessary Rust functions and data structures for running lifting line simulations. This allows for scripting the setup and execution of simulations using Python. More information about the interface will often be mentioned throughout the rest of the book, as well as a high-level description that can be found here. - The Functional Mockup Interface, implemented in the

StormbirdLiftingLineFMU. This interface is more restricted in what it can do, relative to the Python interface, but serves as a practical way to execute sail simulations together with other FMU-models representing the ship. More information about the FMU-interface can be found here - The OpenFOAM interface for running actuator line simulations with OpenFOAM as the CFD solver. This interface is yet to be described in this book. To come.

General about input and output

Stormbird, as any library, consist of many data structures. Some represents the settings for a simulations, such as wake and solver parameters, while others represent input to or result from a simulation. To create and run a simulation it is generally necessary to pass information to the library about the data structures that you whish to create. This is the case for all the interfaces.

To facilitate simple serialization and deserialization - at least from a coding perspective - Stormbird relies heavily on the Serde library. This is "[..] a framework for serializing and deserializing Rust data structures efficiently and generically". In other words, it is a library to automate the conversion of data structures to and from different file formats. Serde supports many formats, but JSON has been chosen for Stormbird. This means that any input must be passed as JSON strings, and output will often also be delivered as JSON strings.

Working with Stormbird is therefor often a matter of setting up the right input in a JSON format and then reading and parsing the output from the resulting JSON format.

Throughout this book there will be examples of data structures shown as Rust code. This is generally to show the available fields in a structure, to give an impression of which variables it is possible to set. All of these Rust-structures has a corresponding JSON representation. A simple example of how a generic Rust structure is converted to a JSON string from Serde is shown below.

An example of a Rust struct first:

#![allow(unused)] fn main() { pub struct SpatialVector { pub x: f64, pub y: f64, pub z: f64, } }

Then the corresponding JSON version with the input data

{

"x": 1.0,

"y": 0.0,

"z": 1.2

}

An example of a complete input string to Stormbird can be seen below. More explanations about this input will come later:

{

"line_force_model": {

"wing_builders": [

{

"section_points": [

{"x": 125.0, "y": 0.0, "z":-20.0},

{"x": 125.0, "y": 0.0, "z":-60.0}

],

"chord_vectors": [

{"x": -8.0, "y": 0.0, "z": 0.0},

{"x": -8.0, "y": 0.0, "z": 0.0}

],

"section_model": {

"Foil": {}

}

},

{

"section_points": [

{"x": 45.0, "y": 0.0, "z": -20.0},

{"x": 45.0, "y": 0.0, "z": -60.0}

],

"chord_vectors": [

{"x": -8.0, "y": 0.0, "z": 0.0},

{"x": -8.0, "y": 0.0, "z": 0.0}

],

"section_model": {

"Foil": {}

}

}

],

"nr_sections": 10

},

"simulation_mode": {

"Dynamic": {

"wake": {

"ratio_of_wake_affected_by_induced_velocities": 0.25

},

"solver": {

"damping_factor": 0.2,

"max_iterations_per_time_step": 3

}

}

},

"write_wake_data_to_file": true,

"wake_files_folder_path": "output/wake_files"

}

Default values

Default values are often given for structures representing settings or models. This means that it may not be necessary to specify every field in a structure in the input. For instance, in the example above, the "wake" structure only has one specified variable. However, the complete wake structure has 12 fields, where some are other structures with more sub fields. The reason only the "ratio_of_wake_affected_by_induced_velocities" is given above is that this was the only setting where a different value than the default was wanted.

The goal is to implement reasonable default values on as many variables as possible.

Helper library to create the right JSON settings

Much of the setup of Stormbird models can be done using a Python library called stormbird_setup. This library is implemented independent of of the core library, and should be useful for all interfaces. It makes different settings available as Python classes that inherits from the Pydantic BaseModel. This makes serializing of the data structures straight forward, and the setup of the models come with typed check validation. That is, the only purpose of the library is to ease the generation of the right JSON strings, and can therefore be used no matter how stormbird is executed, and in combinations with manually generated strings if that is needed. The library also implements some high-level shortcut-functionality for generating typical simulation settings for different cases. See the package folder on GitHub or the examples in the pyfoamsetup folder for more on how to use stormbird_setup

Python interface

The Python interface to Stormbird is made using a Rust library called PyO3. As a general principle, there is a one-to-one relationship between the functionality available in Python and Rust equivalent functionality. That is, names are kept identical in both languages, and the programming constructs are kept as similar as possible (e.g, data structures in Rust becomes classes in Python, etc.)

Examples of how to use the Python functionality can be found in the pystormbird examples folder at the Stormbird github page

Installation

To build and install the package, it is necessary to have a Rust compiler installed on your system as well as Python. With this in place, in should be as easy as a normal pip installation.

For instance, you can navigate to the pystormbird folder in a terminal and execute

pip install .

Still a lot of JSON input and output

Only a limited set of the Rust library has a direct Python interface. For instance, data structures that primarily contains input, and which are therefore not needed directly in a high-level interfaces (such as builder structures) do not have a direct implementation in pystormbird. It is generally seen as uncesseary as the same settings can be passed as JSON strings, which are then deserialized into the right structures on the Rust side. Avoiding a direct Python implementation drastically reduces the development overhead when, for instance, something changes in the core library.

As such, even when using the Python interface to Stormbird, the task is often to create and pass in the right formatted JSON strings to, for instance, initializer methods to create new objects. This is, however, fairly simple as Python has excellent support for converting dictionaries into JSON strings. In addition, the stormbird_setup library can ease the creating of JSON strings in most situations.

An example of how this works is shown below, where a multi-element foil model for a Stormbird simulation is created from input data that is set up as Python dictionaries, which are then converted to a JSON string:

import numpy as np

import json

from pystormbird.section_models import VaryingFoil

# Parameters for the model, representing the foil forces at different lap angles

flap_angles = np.radians([0, 5, 10, 15])

cl_zero_angle = np.array([0.0, 0.3454, 0.7450, 1.0352])

mean_stall_angle = np.radians([20.0, 19.0 , 17.8, 16.5])

cd_zero_angle = np.array([0.0101, 0.0154, 0.0328, 0.0542])

cd_second_order_factor = np.array([0.6, 0.9, 1.2, 1.5])

# Loop over the parameters to create individual foil models

foils_data = []

for i_flap in range(len(flap_angles)):

foils_data.append(

{

"cl_zero_angle": cl_zero_angle[i_flap],

"cd_zero_angle": cd_zero_angle[i_flap],

"cd_second_order_factor": cd_second_order_factor[i_flap],

"mean_stall_angle": mean_stall_angle[i_flap]

}

)

# Collect the foil models into a "varying foil" model

foil_dict = {}

foil_dict["internal_state_data"] = flap_angles.tolist()

foil_dict["foils_data"] = foils_data

# Generate a JSON input string

input_str = json.dumps(foil_dict)

# Pass it to the Stormbird library

foil_model = VaryingFoil(input_string)

The same example with the stormbird_setup library would look like this:

import numpy as np

from pystormbird.section_models import VaryingFoil

# General structures for storing the right variables in a class

from stormbird_setup.direct_setup.section_models import Foil

# Change the name of the VaryingFoil class from stormbird_setup to avoid name clash

from stormbird_setup.direct_setup.section_models import VaryingFoil as VaryingFoilSetup

# Parameters for the model, representing the foil forces at different lap angles

flap_angles = np.radians([0, 5, 10, 15])

cl_zero_angle = np.array([0.0, 0.3454, 0.7450, 1.0352])

mean_stall_angle = np.radians([20.0, 19.0 , 17.8, 16.5])

cd_zero_angle = np.array([0.0101, 0.0154, 0.0328, 0.0542])

cd_second_order_factor = np.array([0.6, 0.9, 1.2, 1.5])

# Loop over the parameters to create individual foil models

foils_data = []

for i_flap in range(len(flap_angles)):

foils_data.append(

Foil(

cl_zero_angle: cl_zero_angle[i_flap],

cd_zero_angl: cd_zero_angle[i_flap],

cd_second_order_factor: cd_second_order_factor[i_flap],

mean_stall_angle: mean_stall_angle[i_flap]

)

)

# Collect the foil models into a "varying foil" model

varying_foil_setup = VaryingFoilSetup(

internal_state_data = flap_angles.tolist(),

foils_data = foils_data

)

# Pass it to the Stormbird library

foil_model = VaryingFoil(varying_foil_setup.to_json_string())

Functional Mockup Unit

The lifting line functionality in Stormbird is available as a Functional Mockup Unit, which means that the functionality can be executed through the Functional Mockup Interface standard. The actual interface is generated using the fmu_from_struct library, which is made by the same developer as Stormbird.

How to execute simulations using the FMU-version

The FMU-version is currently made to support version 2 of the FMI-standard. This choice is made because the developers of Stormbird primarily uses the Open Simulation Platform for executing simulations, which currently only supports version 2. An FMU that supports version 3 of the FMI-standard is relatively straight forward to make, but will probably not be prioritized before the Open Simulation Platform is updated to the latest version.

A simulation can be executed with any simulation platform that supports the FMI-standard. One example is the command line interface from the Open Simulation Platform, or some Python interface to FMU's such as FMPy or PyFMI.

To actually set up a simulation, it is necessary to pass in several parameter- and input variables to the FMU unit. For a full overview of the available variables, see the FMU source code. To see how it can be used in practice, see the FMU example folder.

What can the FMU-version do?

The FMI-interface inherently comes with more limitations than a conventional API, such as the Python interface. For instance, there are limitations on what type of variables that can be passed to and from different FMUs, and there is a specific order to how functions are executed. Although there are many ways to work around these limitations, the FMU-version of Stormbird is, for simplicity sake, designed to only cover the most typical use cases for running dynamic lifting line simulations. That is, it is not intended to be a direct alternative to the Python interface, but rather a specialized way to use some of the functionality.

To be more specific, there are essentially two primary use cases for the Stormbird FMU:

- Coupling of Stormbird to a time-domain ship simulator, such as VeSim. VeSim is a ship simulator that includes maneuvering and seakeeping models of ships. It can, for instance, simulate a ship moving in waves, including the effect of rudder action and control systems. The software is built around the FMI-standard to couple different sub-models together. Stormbird can, therefore, be one of many models in a ship-system simulations in the time-domain.

- Running sail simulations in hybrid experiments. Hybrid experiments are experiments where part of the physics is measured experimentally, while other parts are simulated. In the specific case of wind-powered ships, the aerodynamic forces on the sails are simulated while the hydrodynamics are tested in a towing tank. This article explains more of how this is done at SINTEF Ocean. The Stormbird FMU was designed to fit well with the laboratory software used at SINTEF Ocean when doing hybrid tests, called HLCC.

There are no direct coupling to VeSim or HLCC in the Stormbird FMU, but the choice of input and output variables was made, in part, based on what makes sense for these external software packages. That is, the design of the Stormbird FMU interface is not made in isolation.

OpenFOAM version

OpenFOAM is a general open source CFD solver, widely used both in academia and in industry.

The OpenFOAM version of Stormbird is currently the only way to run actuator line simulations. It consist of a volume force interface between the Stormbird library and the OpenFOAM library, that can be activated together with a solver in OpenFOAM. More details about this interface can be found both in the actuator line chapter and the specific chapter about the OpenFOAM interface.

As a general not, this interface could also serve as an inspiration for how to connect Stormbird to other CFD solvers, if this turns out to be relevant in the future.

Line model representation of wings

The fundamental building block of all the methods in Stormbird is a simplified line representation of the lifting surfaces. This means that the full geometry of the wings is reduced to multiple discrete line elements. Each line element represents a section of a lifting surface that has the following properties:

- A line segment geometry, represented as a start point and and end point, defining the location and orientation of the element. The line segment also has control point, defined to be in the middle of the line segment. This point is used when computing local flow properties for the element during a simulation.

- A chord vector, which defines both the orientation and length of the chord. The orientation is relevant for computing the angle of attack as a function of the local velocity, while the length is relevant for computing the magnitude of the forces.

- A sectional model which is used to compute lift- and drag coefficients as a function of the local flow properties. The line model itself makes no assumptions about how the lift and drag is computed. However, Stormbird comes with a limited set of sectional models that are further described in Sectional models. Note: in the actual implementation, the section model is not actually stored for each line element, because most of the time, many elements will share the same sectional model. However, when iterating over line elements in the code there is a functionality to retrieve the relevant sectional model for that line element.

Structure overview

A view of source code that defines a line force model data structure can be seen below to illustrate what data is available. There are also multiple methods connected to this data structure not shown here. The construction of a line force model is generally not done manually, but rather by a builder.

#![allow(unused)] fn main() { pub struct LineForceModel { pub span_lines_local: Vec<SpanLine>, pub chord_vectors_local_not_rotated: Vec<SpatialVector>, pub chord_lengths: Vec<f64>, pub section_models: Vec<SectionModel>, pub wing_indices: Vec<Range<usize>>, pub non_zero_circulation_at_ends: Vec<[bool; 2]>, pub density: f64, pub circulation_correction: CirculationCorrection, pub angle_of_attack_correction: AngleOfAttackCorrection, pub output_coordinate_system: CoordinateSystem, pub rigid_body_motion: RigidBodyMotion, pub local_wing_angles: Vec<f64>, pub chord_vectors_local: Vec<SpatialVector>, pub chord_vectors_global: Vec<SpatialVector>, pub chord_vectors_global_at_span_points: Vec<SpatialVector>, pub span_lines_global: Vec<SpanLine>, pub span_points_global: Vec<SpatialVector>, pub ctrl_points_global: Vec<SpatialVector>, pub ctrl_point_spanwise_distance: Vec<f64>, pub ctrl_point_spanwise_distance_non_dimensional: Vec<f64>, pub ctrl_point_spanwise_distance_circulation_model: Vec<f64>, pub input_power_models: Vec<InputPowerModel>, } }

More details on each field can be found in the code documentation. The construction of a line force model is generally not done with the structure directly, but rather through a builder

Building a line model

As shown in the intro section, a line model consist of many line elements. To simplify the construction of this line model, Stormbird uses a line force model builder that helps with at least two things:

- Reduce the amount of input data: Rather than having to specify data directly for each line element, it is possible to only specify data at some chosen points along the span - such as the beginning and the end - and let the builder interpolate for every line segment between the specified points

- Automate the setup of multiple wings: The line force model requires information about which line element belongs to which wing. This can be cumbersome to set up manually, and it is not really necessary to do so. The builder automatically keep tracks of which line element belong to which wing.

Input data

The Rust definition of the builder structure looks like the following:

#![allow(unused)] fn main() { pub struct LineForceModelBuilder { pub wing_builders: Vec<WingBuilder>, pub nr_sections: usize, pub density: f64, pub circulation_correction: CirculationCorrectionBuilder, pub output_coordinate_system: CoordinateSystem, pub local_wing_angles: Vec<f64>, pub rotation: SpatialVector, pub translation: SpatialVector, } }

The only required input is the vector containing WingBuilder structures and the nr_sections 1. The nr sections should be tested for each project, and will affect both the accuracy and the computational speed. Typical values range between 10-50. The density is set to the standard air density for 15 degrees Celsius by default ( which = 1.225 kg / m^3).

The circulation_corrections is an enum, where the default variant is None, and therefore not used by default. There will be more on the circulation corrections option later. This is only used in special circumstances, for instance when a pure lifting line simulation might fail due to numerical issues.

The output_coordinate_system is an enum that specifies how the forces and moments from the line force model should be calculated. The default is Global, which means all values are in a global coordinate system. That is, the coordinate system for the forces are not moved even if the wings are moved during a simulation. The other option is to set it to Body. In this case, the coordinate system of the forces will always follow the wings when they are moved.

The local_wing_angles, rotation, and translation specifies the initial values for the local rotation of the wing angles as well as the global rotation and translation of the whole line force model. See the move line models chapter for more.

Wing builder

A wing builder contain data to build line segments for a single wing. When a vector (or list) of wing builders are provided, the LineForceModelBuilder will automatically keep track of which line segment belong to each wing. The fields in a WingBuilder structure is as shown as Rust code below:

#![allow(unused)] fn main() { pub struct WingBuilder { pub section_points: Vec<SpatialVector<3>>, pub chord_vectors: Vec<SpatialVector<3>>, pub section_model: SectionModel, pub non_zero_circulation_at_ends: [bool; 2], pub nr_sections: Option<usize>, } }

The input consist of a set of section_points which contain information about the span line position. The minimum number of section points is two, and the first has to start at one end of the wing, while the last must end up at the other. There can, however, also be more section points in between the ends.

For each section point, there also needs to be chord_vectors, which specify the local chord at the points. The chord_vectors give information about both chord length and orientation.

Each wing also needs a sectional model. The sectional model can differ between different wings given to the LineForceModelBuilder, which is useful for cases where different sail types are installed on the same ship (uncommon today, but might happen in the future).

The non_zero_circulation_at_ends is boolean values that specifies the expected behavior of the circulation distribution at the ends of the wing. It is used when initializing the circulation distribution before a simulation, and when applying corrections to the circulation distribution. In most cases, the expected value of the circulation strength at the ends is zero, and the value of this variable should be [false, false]. However, if, for instance, the wing is standing directly on a symmetry plane, or is directly coupled to another wing, the circulation distribution will typically not be zero. If an end is coupled to something that might give a non-zero circulation, then that end should then get a true value. For instance, if the first end is standing on a symmetry plane, the value of this variable should be [true, false].

The nr_sections variable is optional but can be set for each wing to override the default parameters in the LineForceModelBuilder. Typically, it will not be used, as the most common scenario is to have the same number of sections for each wing.

When building a line force model from a wing builder, the wings are divided into multiple line segments based on the data in the WingBuilder structure. Each point in between the specified points are linearly interpolated 2

Input to methods

In many cases, the methods in Stormbird will handle the actual building of the line force models automatically, using a builder structure as input. That is, the input to some function is often the builder and not the line force model itself. For instance, when setting up a lifting line simulation in Python, you only have to supply the builder data, and the line force model will be built automatically internally.

However, it is also possible to convert a builder into a line force model. This happens by calling the build() method, as usual for Rust builder structures.

-

The number of sections for set in the

LineForceModelBuilderis used as default, except when another value is defined in theWingBuilderbelow. ↩ -

The interpolation method is possible to change or update to something that can handle non-linear changes between section points. This is, however, so far not prioritized as most sail types tend to use fairly simple geometrical structures. This might change in the future if there is a need to do so. ↩

Circulation strength

The circulation strength along a wing determines both the magnitude of the lift-forces and the induced velocities from the wing. The velocity is affected either through induced velocities from a wake model based on potential theory, in the case of lifting line simulations, or through body forces projected into a CFD domain, in the case of actuator line simulations.

This chapter specifies how the circulation strength is estimated from the local velocity on each line section, and how it is possible to modify the estimation for stability purposes. The procedure is the same for all simulation methods in Stormbird. That is, there are no differences in this regard between the static lifting line, dynamic lifting line or the actuator line. The responsibility for calculating the values are therefore given to the line force model.

Raw lifting line theory estimation

The calculation of the circulation strength on each line element follows the Kutta–Joukowski theorem. The mathematical definition of the circulation value, \( \Gamma \), on a line element is as follows, where \(U \) is the velocity, and \( L \) is the lift per unit span.

\[ \Gamma = L / (U \rho) \]

The lift per unit span is further computed from the sectional lift coefficient, \(C_L\) as follows, where \(\rho\) is the density and \(c \) the chord length:

\[ L = 0.5 \cdot \rho \cdot c \cdot C_L \cdot U^2 \]

When these equations are combined, we get the following equation for the circulation strength:

\[ \Gamma = 0.5 \cdot c \cdot C_L \cdot U \]

The actual source code looks like the following (the negative values are to account for directional definitions)

#![allow(unused)] fn main() { pub fn circulation_strength_raw(&self, velocity: &[Vec3]) -> Vec<f64> { let cl = self.lift_coefficients(&velocity); (0..velocity.len()).map(|index| { -0.5 * self.chord_vectors_local[index].length() * velocity[index].length() * cl[index] }).collect() } }

Optional corrections

Sometimes, there might be noise in the estimated circulation strength, which might cause instabilities and errors in the estimated forces. A typical examples is lifting line simulations of stalled wings - especially when the lift coefficient is very large.

To handle such cases in a practical manner, there are optional corrections methods that can be used when estimating the circulation strength. These methods are controlled through a CirculationCorrection enum that is specified for the line force model. To set up different types of corrections, a CirculationCorrectionBuilder is used, which has the following structure:

#![allow(unused)] fn main() { pub enum CirculationCorrectionBuilder { None, Prescribed(PrescribedCirculation), Smoothing(CirculationSmoothingBuilder), } }

The default variant is None, which means that no corrections are applied. The effect of the other variants are explained below.

Smoothing

The smoothing correction applies different types of smoothing filters to the estimated circulation, controlled through the following structure:

#![allow(unused)] fn main() { pub struct CirculationSmoothingBuilder { pub smoothing_type: SmoothingTypeBuilder, pub prescribed_to_subtract_before_smoothing: Option<PrescribedCirculation>, } }

The option to add a prescribed_to_subtract_before_smoothing is currently. It subtracts a prescribed circulation distribution (see more about this below) from the estimated circulation before applying the smoothing filter. After the smoothing is applied, the prescribed distribution is added back to the smoothed result. The idea behind this is that it can avoid issues with smoothing the rapidly changing circulation at the wing tips. By subtracting a known distribution first, the smoothing filter only needs to handle the more noisy part of the circulation distribution. However, the this feature is still experimental, and should be used with care.

The smoothing_type field specifies which type of smoothing filter should be applied. The available options are shown below:

#![allow(unused)] fn main() { pub enum SmoothingTypeBuilder { Gaussian(GaussianSmoothingBuilder), CubicPolynomial(CubicPolynomialSmoothingBuilder), } }

The first smoothing type is Gaussian smoothing filter. The available fields are shown below:

#![allow(unused)] fn main() { pub struct GaussianSmoothingBuilder { pub smoothing_length_factor: f64, pub number_of_end_points_to_interpolate: usize } }

The smoothing_length_factor gives a factor used to calculated the smoothing length from the span of each wing in the line force model. That is, if the value is set to 0.01, the smoothing length will be 1% of the total span of each wing, independent of the value of the wing span or the number of sections.

The number_of_end_points_to_interpolate field specifies how many points at each end of the wing that should be inserted beyond the tips of the wings before applying the smoothing. Which values that are inserted beyond the tips are dependent on wether the circulation is expected to be zero or not, controller by the non_zero_circulation_at_ends field in the line force model. If the circulation is expected to have zero circulation, the additional points are set to zero. If not, the values are linearly extrapolated from the inner points. If this value is not set, the default will be to calculate the number of insertion points based on the smoothing length and the number of sections. This should be sufficient in most cases.

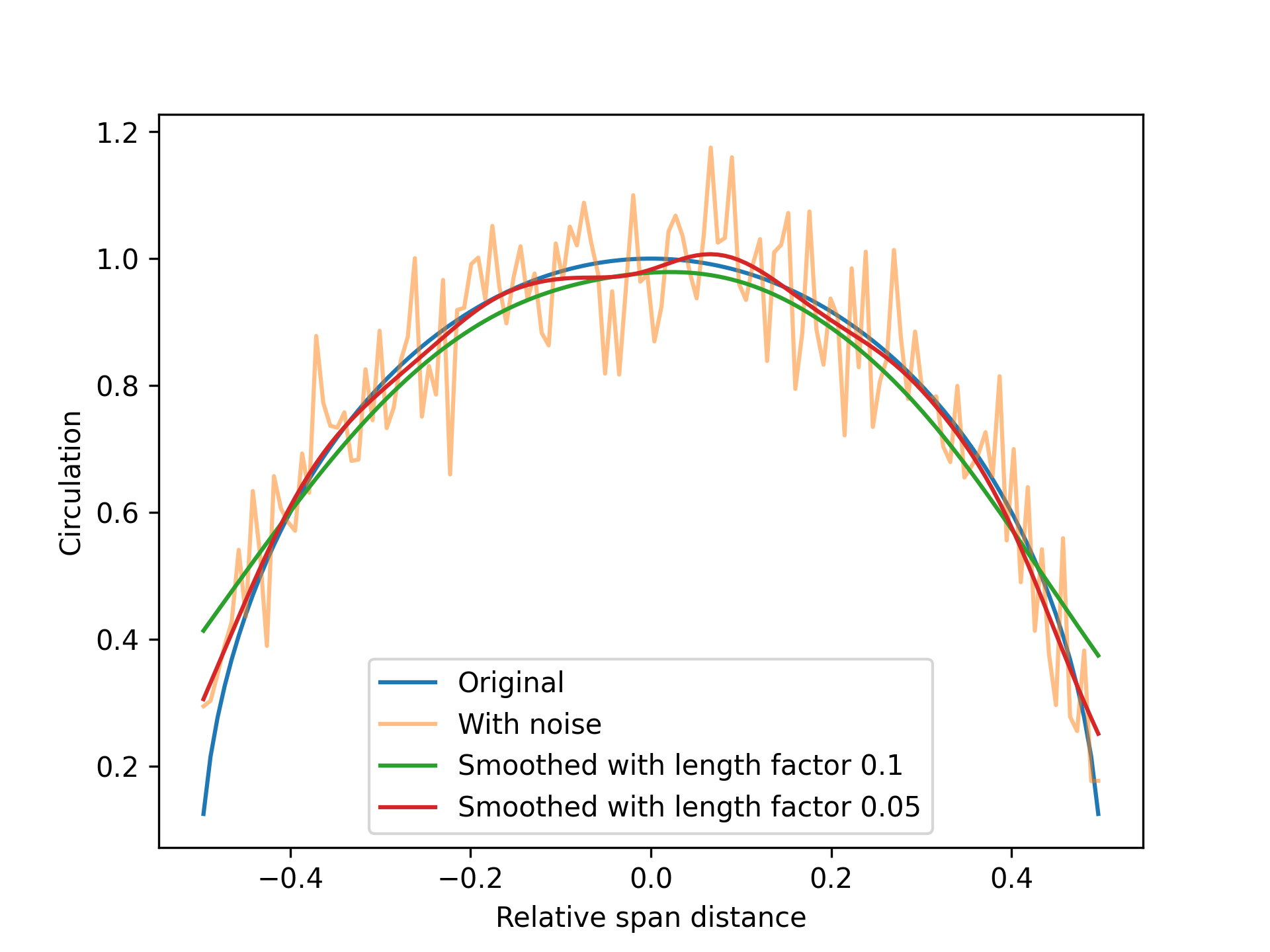

An example of how this smoothing method affects the circulation distribution is illustrated in the figure below. Note: the example is with an excessive amount of noise, and is not representative of actual numerical noise from a lifting line simulation. Rather, it shows an example where an artificial elliptic circulation distribution was first generated, and then modified by adding random numerical noise. The plot then shows how the noise is reduced when the noisy circulation distribution is corrected using the Gaussian smoothing filer, with different values for the gaussian_length_factor.

As can bee seen, simple Gaussian smoothing introduces some errors towards the end of the wings if the smoothing length is too large, although the random noise is effectively reduced. It is therefore generally recommended to only apply as little smoothing as necessary to stabilize a solution.

The second smoothing type is a cubic polynomial smoothing filter, which assumes that a cubic polynomial can be fitted to the points with a certain window_size. The larger the window size, the more smoothing is applied. The available fields are shown below:

#![allow(unused)] fn main() { pub enum WindowSize { Five, Seven, Nine } pub struct CubicPolynomialSmoothingBuilder { pub window_size: WindowSize, } }

Prescribed distribution

Predetermined circulation distributions are a special mode where the circulation is forces to always follow a simple mathematical shape. For instance, it is possible to force the distribution to always be elliptical. This gives very stable simulations, and sometimes results that are very close a full simulation. It is particular useful if the goal is only to estimate interaction effects between wings, but where the lift and drag for a single wing is already known from, for instance, experimental or CFD results.

A view of the PrescribedCirculation structure:

#![allow(unused)] fn main() { pub struct PrescribedCirculationShape { pub inner_power: Float, pub outer_power: Float, } pub struct PrescribedCirculation { pub shape: PrescribedCirculationShape, pub curve_fit_shape_parameters: bool, } }

The option to curve_fit_shape_parameters is currently experimental. It will curve fit the shape parameters to the raw circulation distribution before applying the prescribed shape. However, it currently ends up with a relatively slow simulation, and the final results are not always better than just using default values for the shape parameters. It is set to false by default, and tuning it on should be used with care and testing.

The PrescribedCirculationShape parameters in the structure is used to force the circulation to always follow a mathematical shape that looks like the equation below, where \(s\) is the local non-dimensional span distance, varying from -0.5 to 0.5 along each wing:

\[ \Gamma(s) = \Gamma_0 (1.0 - (2 s)^{\text{inner_power}})^{\text{outer_power}} \]

The default values are to set inner_power to 2.0 and outer_power to 0.5. This corresponds to an elliptic distributions.

Move and modify a line model

In dynamic simulations, it will often be interesting to apply motion to the sails and dynamically change the angle of attack or internal state of a section model. This can, for instance, be done to simulate how the sails affect the seakeeping or maneuvering abilities of a ship or to allow the operational variables of the sails be dependent on the current wind conditions. This chapter specifies how to apply motion data to the sails during a dynamic simulation and how to modify the operational variables for each sail.

Motion variables

The motion of a line force model is specified by the rigid_body_motion field, which is of the RigidBodyMotion type. This structure looks like the following:

#![allow(unused)] fn main() { pub struct RigidBodyMotion { pub translation: SpatialVector, pub rotation: SpatialVector, pub velocity_linear: SpatialVector, pub velocity_angular: SpatialVector, pub rotation_type: RotationType, } }

It specifiies translation and rotation, both in terms of the curren positions and in terms of the velocities at any given time. The position is important both for updating the wake shape and for determining local wind conditions on each line segment. When applying the motion variables, the rotation will be applied first, then the translation. That is, the rotation happens around a local coordinate system always. The order of the rotation can be set with the rotation_type field, but the default is rotation in x first, then y, and then z.

The motion velocities, velocity_linear and velocity_angular, are important for the calcualtion of forces. The forces on the each line segment is primarily dependent on the local velocity, local angle of attack, and the internal state of the sectional models. As such, when a motion is applied to the line force model, it is necessary to calculate the felt velocity and felt acceleration of each line segment, so that this can further be used as input to the force calculation functions. This can be calculated from the gloabl rotation and translation velocity vectors using methods in the RigidBodyMotion structure. As will be further highlighted later, the forces are estimated from a SectionalForceInput structure, which have fields as shown in the code block below. The velocity and acceleration values calculated in the SectionalForceInput structure are dependent on the motion of the sails.

#![allow(unused)] fn main() { pub struct SectionalForcesInput { pub circulation_strength: Vec<f64>, pub velocity: Vec<SpatialVector>, pub angles_of_attack: Vec<f64>, pub acceleration: Vec<SpatialVector>, pub rotation_velocity: SpatialVector, pub coordinate_system: CoordinateSystem, } }

Each element in the vectors in the SectionalForceInput corresponds to a line element in the LineForceModel. Both the velocity and the acceleration is a combination of freestream conditions, induced velocities, and motion velocities. The motion velocities can either be automatically calcualted based on fintie difference and the time history of the motion or set manually if the variables are available from some other sources (e.g., a rigid body solver of a ship)

Control variables

Two types of control variables exist for the sails in a LineForceModel.

The first is the local_wing_angles, which defines the rotation of the sails around its local axis. The local axis is defined as the axis of the first span line. If the sails is defined to be oriented in the z-direction as the span direction, a local wing angle value will then rotate all chord vectors around the z-axis.

The second value is the internal state of the section model for each wing. This value can represent different things, depending on the sail type and how it is modeled. Typical values are flap angles, rotational speeds, and suction rates.

Updating the LineForceModel

When setting new values for either the motion variables or the control variables it is important to do it in way that also updates all dependent internal variables. For instance, many of the variables that define the geometry of the wings are defined both with their local values and their global values (e.g., chord_vectors_local and chord_vectors_global). In general, the global version of a variable type is calcualted from the local one, with the motion and wing angles applied to them. As such, updating the line force model should be done with set methods that also updates the global representation of the line force model.

The line force model have a general update function that should update all global geometry variables, and which should also be called after all set methods.

Motions

Motion can be set in two ways: either with the position and rotation only, and using finite difference to calculate the corresponding velocities due to this motion, or by updating the velocity values manually. The first option is generally the easiest. However, the latter might be useful in cases where motion velocity is available from an external source, such as a rigid body solver that integrates the acceleration of an entire ship.

Below is some examples of how to apply different motion variables through the Python interface.

import numpy as np

from pystormbird.lifting_line import Simulation

# ----- code to set up the simulation first, which includes the line force model -----

simulation = Simulation(setup_string)

translation = [1.0, 2.0, 3.0]

rotation = np.radians([10.0, 0.0, 0.0]).tolist()

time_step = 0.1

# Update the translation and rotation with the velocity set by finite difference

simulation.set_translation_and_rotation_with_finite_difference_for_the_velocity(

time_step = time_step,

translation = translation,

rotation = rotation

)

# Alternativluy, update everything manually

simulation.set_translation_only(translation)

simulation.set_rotation_only(rotation)

linear_velocity = [8.0, 0.0, 0.0]

angular_velocity = np.radians([0.0, 10.0, 0.0]).tolist()

simulation.set_velocity_linear(linear_velocity)

simulation.set_velocity_angular(angular_velocity)

Local chord angle control

Updating the chord angles in the Python interface is done by set-method that takes a list of angles as input, that must have a length equal to the number of wings in the line force model. An example code snippet is shown below, for a case with three sails:

import numpy as np

# some code to set up the simulation, as above

simulation.set_local_wing_angles(

np.radians([40.0, 35.0, 30.0]).tolist()

)

Update the internal state

The internal state of the section models can be updated with a set method, similar to how the local wing angles can be updated. This is shown in the code example below:

import numpy as np

# some code to set up the simulation, as above

simulation.set_section_models_internal_state(

np.radians([10, 12.5, 15]).tolist()

)

Force calculations

An important job for the line force model is to compute forces on each line element, as a function of the local flow variables. The results from these calculations are available in the result-structures from a simulation. A view of the result structure is shown as Rust code below. There is also a Python interface to this structure where the same fields are available.

#![allow(unused)] fn main() { pub struct SimulationResult { pub ctrl_points: Vec<SpatialVector<3>>, pub force_input: SectionalForcesInput, pub sectional_forces: SectionalForces, pub integrated_forces: Vec<IntegratedValues>, pub integrated_moments: Vec<IntegratedValues>, pub iterations: usize, pub residual: f64, } }

Sectional vs integrated

The forces on a line force model is specified both as sectional values and as integrated values. As the name suggest, the sectional forces are forces acting on each individual section in the line force model. That is, the force acting on a single line element. The integrated forces and moments are the sum of sectional forces for each wing in the line force model. That is, the length of the integrated forces and moments vectors will be equal to the number of wings.

Force types

There are four different force types in Stormbird, which are estimated from different methods. Each force type has a dedicated section below

1 - Circulation forces

The first, and usually most important, force component is the force that arise from the circulation on each line segment. The circulation strength is estimated directly from the local velocity and sectional model, as described here. The direction of the force is always normal to the local velocity.

The resulting force from the circulation strength is therefore just the "lift" on each line segment, but in the coordinate system of the local flow. Due to the presence of induced velocities, the sectional lift may cause both lift and drag relative to the incoming free stream. Circulation forces are, in other words, the combination of lift and lift-induced drag from the simulation.

2 - Sectional drag

Sectional drag is, usually1, the viscous drag on each line segment. It is calculated directly from the drag function in the sectional model. The direction is always parallel to the local flow.

3 - Added mass

Added mass forces are the forces that are proportional to the acceleration of the foil section. The magnitude of the force is determined by the added mass coefficients set in the sectional model and the acceleration. The foil-models only result in added mass forces due to acceleration in the direction normal to the chord vectors. For the rotating cylinder, the added

Note: for now, the default value of the added mass coefficient is set to zero. This is because the feature is currently lacking a proper test case. Must therefore be used with care!

4 - Gyroscopic

The gyroscopic force/moment is only applicable to rotor sails. It is the gyroscopic precision due to the rotation of the cylinders. It is dependent on the 2D moment of inertia, which needs to be specified for the sectional model in order to make this force non-zero.

Force results structures

To allow for a comparison between the force types - for instance in debugging situations - each force type is stored separately, in addition to the total force / moment. The structures used to store this data is shown below:

#![allow(unused)] fn main() { pub struct SectionalForces { pub circulatory: Vec<SpatialVector<3>>, pub sectional_drag: Vec<SpatialVector<3>>, pub added_mass: Vec<SpatialVector<3>>, pub gyroscopic: Vec<SpatialVector<3>>, pub total: Vec<SpatialVector<3>>, } }

#![allow(unused)] fn main() { pub struct IntegratedValues { pub circulatory: SpatialVector<3>, pub sectional_drag: SpatialVector<3>, pub added_mass: SpatialVector<3>, pub gyroscopic: SpatialVector<3>, pub total: SpatialVector<3>, } }

-

It is perfectly fine to include more than the viscous drag in the sectional drag model, if, for instance, it is necessary to add some empirical corrections to the total drag estimate. What exactly the sectional drag represents from a purely physical point of view must be decided on when setting up the model by the user. ↩

Input power

Some sail types, like rotor sail and suction sails require input power to operate. This is modeled entirely empirically in Stormbird. The structure that controls these models are shown below.

MORE TO COME ON THIS LATER

#![allow(unused)] fn main() { pub struct InputPowerData { pub section_models_internal_state_data: Vec<Float>, pub input_power_coefficient_data: Vec<Float>, } pub enum InputPowerModel { NoPower, FromInternalStateAlone(InputPowerData), FromInternalStateAndVelocity(InputPowerData), } }

Section models

The primary purpose of the sectional models is to compute non-dimensional lift and drag as a function of the local flow velocity at each each line element. That is, they are two-dimensional models which is used together with the chord vector and local flow velocity to compute the total force on each line section. In both lifting line and actuator line simulations, three-dimensional effects are modeled by altering the effective velocity experienced by these two-dimensional models.

Different sectional models are necessary for different sail types. This is handled by implementing the sectional model as an enum, with a definition as shown below:

#![allow(unused)] fn main() { pub enum SectionModel { Foil(Foil), VaryingFoil(VaryingFoil), RotatingCylinder(RotatingCylinder), } }

Each variant in this enum has its own sub-chapter for more details. A short overview is given below:

Foilrepresents a model for a single element foil profile, and is suitable for modelling single element wing sailsVaryingFoilis a model that extends theFoilmodel to allow the output to be dependent on some internal variable. The internal variable can for instance be a flap angle, for a two-element foil, a combination of multiple element configurations, for instance to model a three-element foil, or suction rate when modelling a suction sail.RotatingCylinderrepresent a cylinder where the rotational speed can be varied to alter the force output. This is intended to be used to model rotor sails.

More sectional models can be added in the future. The only requirement is that each model must be able to compute the necessary force coefficients. However, the goal is to cover most use cases with these three core models. Since the models are handled through an enum, they may require different inputs in their own functions for calculating lift and drag. For instance, the Foil and VaryingFoil models require the angle of attack as input, while the RotatingCylinder takes the velocity magnitude and local chord length (or diameter) as input. The right input is managed by the line force model structure, and is not something the user needs to think about when running a simulation.

To get an overview of how to set up the different variants, see the sub-chapters for each model.

Foil model

The Foil structure is a parametric model of a single element foil section. That is, it is defined using (relatively) few parameters that are later used in a simple mathematical model to compute lift and drag for arbitrary angles of attack.

Why a parametric model?

Other implementations of lifting line and actuator line methods often use data based models for computing the lift and drag coefficients. That is, the user must supply data on how the lift and drag varies as a function of the angle attack, and then the solver can use this data together with interpolation or table look-up to compute force coefficients for arbitrary angles.

A data based approach is often fine, and does have some benefits. For instance, it is the only way to make a truly general model where the user have full control over the behavior of the sectional model. For this reason, there might be implementations of pure data based models in Stormbird in the future. However, the choice of using a parametric model for now where based on three reasons.

First, it becomes easier to use a parametric model as a building block for more complex foil models, where the behavior depends on some internal state, such as flap angle or suction rate. This is because the model parameters can be allowed to depend on the internal state through interpolation. See the varying foil sub chapter for more on this.

Second, a parametric model ensures smoothness, which is beneficial when using the model together with gradient based optimization algorithms. For instance, such a method might be used to optimize the angle of attack for wing sails at a given wind direction. The smoothness is in particular practical when the expected optimal point is close to the stall angle - which it often is.

Third, tuning a parametric models is generally believed to be easier than a data based model. For instance, lets say you want to adjust the exact stall characteristics of a 2D model, to make a simplified lifting line model better fit with high-fidelity experimental data; this would not be straightforward with a data based model, but should be fairly easy if the parametric model of the lift has good parameters to control the stall behavior.

The downside of a parametric model is believed to be small, as long as the model can represent typical foil section behavior without too many simplifications. The design of the Foil model is intended to achieve this as best as possible1.

Model overview

The model is divided in two core sub-models, labeled pre-stall and post-stall, respectively representing the behavior before and after the foil has stalled due to too high angle of attack.

For angles of attack below stall, it is assumed that both lift and drag can be represented accurately with simple polynomials. The lift is linear by default, but can also have an optional high-order term where both the factor and power of the term is adjustable. The high order term is meant to capture slowly developing separations, which might occur at low Reynolds numbers. The drag is assumed to be represented as a second order polynomial. For a wing sail operating below stall, the drag will mostly be dominated by lift-induced drag forces. The viscous drag can therefore be kept simple, as the importance to the total force is relatively low.

For angles of attack above stall, both the lift and drag are assumed to be harmonic functions which primarily is adjusted by setting the max value after stall. This is a rough model which might not be perfect for all angles of attack, but is assumed to be close enough. A rough and approximate model for the post-stall behavior is assumed to be OK as wing sails and suction sails will most often operate below stall.

The transit between the two models is done using a sigmoid function, where both the transition point and the width of the transition can be adjusted.

In addition, there factors in the model to account for added mass and lift due to the time derivative of the angle of attack. Both these effects are assumed to be linear for simplicity.

Available parameters

A view of the available fields in the Foil model is seen below, with further explanation of each parameter right after:

#![allow(unused)] fn main() { pub struct Foil { pub cl_zero_angle: f64, pub cl_initial_slope: f64, pub cl_high_order_factor: f64, pub cl_high_order_power: f64, pub cl_max_after_stall: f64, pub cd_min: f64, pub angle_cd_min: f64, pub cd_second_order_factor: f64, pub cd_max_after_stall: f64, pub cd_power_after_stall: f64, pub cdi_correction_factor: f64, pub mean_positive_stall_angle: f64,. pub mean_negative_stall_angle: f64, pub stall_range: f64, pub cd_bump_during_stall: f64, pub cd_stall_angle_offset: f64, pub added_mass_factor: f64, } }

An explanation of the parameters are given below:

cl_zero_angle: Lift coefficient at zero angle of attack. This is zero by default, but can be set to a non-zero value to account for camber, flap angle or boundary layer suction/blowing.cl_initial_slope: How fast the lift coefficient increases with angle of attack, when the angle of attack is small. The default value is \( 2 \pi \) , which should always be the values used for a normal foil profile - with or without camber and flap - but it can also be set to different value for instance to account for boundary layer suction/blowing.cl_high_order_factor: Optional proportionality factor for adding higher order terms to the lift. Is zero by default, and therefore not used. Can be used to adjust the behavior of the lift curve close to stall.cl_high_order_power: Option power for adding higher order terms to the lift. Is zero by default, and therefore not used. Can be used to adjust the behavior of the lift curve close to stall.cl_max_after_stall: The maximum lift coefficient after stall.cd_min: Minimum drag coefficient when the angle of attack is equal to theangle_cd_min.angle_cd_min: The angle where the the minimum drag coefficient is reached.cd_second_order_factor: Factor to give the drag coefficient a second order term. This is zero by default.cd_max_after_stall: The maximum drag coefficient after stall.cd_power_after_stall: Power factor for the harmonic dependency of the drag coefficient after stall. Set to 1.6 by default.cdi_correction_factor: factor that can be used to correct for numerical errors in the lift-induced drag. Set to a positive value to increase the drag, and a negative value to decrease the drag. The default is zero, which means no correction.mean_positive_stall_angle: The mean stall angle for positive angles of attack, which is the mean angle where the model transitions from pre-stall to post-stall behavior. The default value is 20 degrees.mean_negative_stall_angle: The mean stall angle for negative angles of attack, which is the mean angle where the model transitions from pre-stall to post-stall behavior. The default value is 20 degrees.stall_range: The range of the stall transition. The default value is 6 degrees.cd_bump_during_stall: Factor to model additional drag when the foil is stalling, but that is not included in the pre- and post-stall drag models. Set to zero by default.cd_stall_angle_offset: Optional offset to the stall angle for the drag coefficient. This can be used to tune the drag curve to better fit experimental data. The default is zero, which means that stall effects on the drag starts at the same angle of attack as for the lift. When the offset is set to any value, the "amount of stall" function is shifted by this value for the case of the drag coefficient only.added_mass_factor: Factor to model added mass due to accelerating flow around the foil. Set to zero by default.

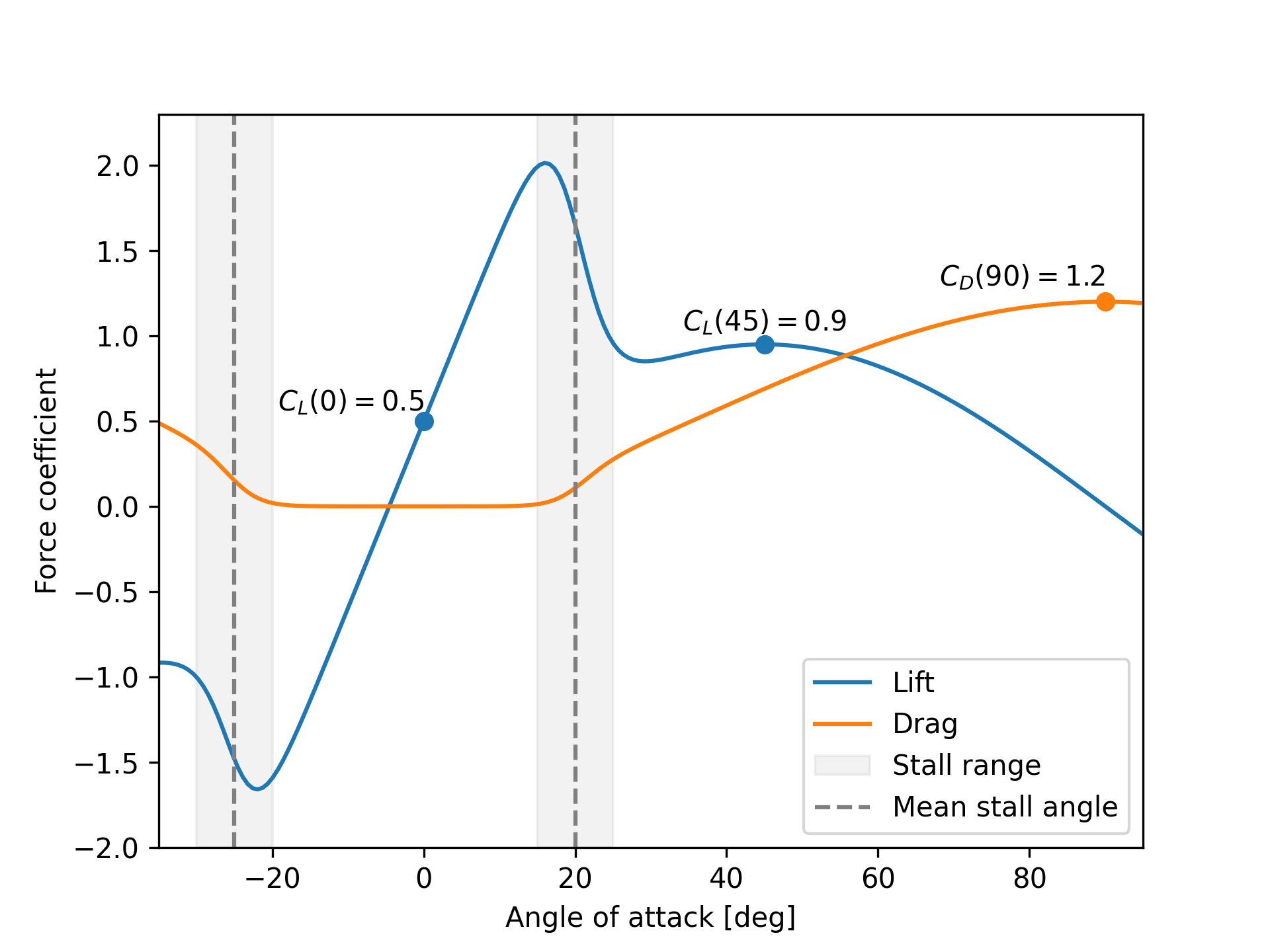

Example

An example of the output of a foil model is shown below. The parameters values are given as follows:

#![allow(unused)] fn main() { let foil = Foil { cl_zero_angle = 0.5, cl_max_after_stall = 0.9, cd_max_after_stall = 1.2, mean_positive_stall_angle = 20.0_f64.to_radians(), mean_negative_stall_angle = 25.0_f64.to_radians(), stall_range = 10.0_f64.to_radians(), ..Default::default() } }

-

The design of the

Foilmodel is open for changes, and may be updated when a need is discovered. The goal is to find the right balance between simplicity and flexibility. ↩

Varying foil model

The VaryingFoil structure is a model of a foil where the output can be allowed to depend on some internal state. The typical example is a flap angle, for a two-element foil, or suction rate, for a suction sail. To achieve this, the varying foil model uses multiple Foil models, each belonging to a specific internal value. Linear interpolation is used for all Foil model parameters for each state between the input data. This interpolation is handled by the VaryingFoil structure whenever a new internal state is set.

How to setup a VaryingFoil structure

As a general case, you need to tune several Foil models for multiple values of whatever you want to use as an internal state of the wing. If this is a flap angle, you would need data for the lift and drag coefficients as a function of angles of attack for multiple discrete flap angles. When a unique model is generated for each value of the flap angle, this can be given as input to the VaryingFoil structure, along with the flap angle data as internal_state_data. An example will come...

What if I want to model a three-element foil?

More complex models with more internal variable might be added in the future. This will be done when the use case represent itself, and likely not before. However, it is still possible to use the VaryingFoil structure to model sails with more control parameters in a slightly simplified way.

For instance, lets assume you want to model a three-element foil, where there is both a flap and a leading edge slot. Currently it is not possible to model changing values of the slot- and flap-angle independently directly in Stormbird. However, if you assume some relationship between the flap angle and the slot angle, the VariableFoil structure can still be used.

This might not be such a large simplification for practical use cases1. The point of a multi-element foil is both to create larger maximum lift forces and to reduce the drag force for a given lift force. In a lifting line model - and also mostly for wings in general - the lift-induced velocities are not very affected by how the lift is created. Rather, it is just the value of the lift-coefficient that matters. For a given wanted lift coefficient it seems reasonable that there is always a single optimum combination of flap- and slot-angle, which probably can be computed independently of three-dimensional effects. As such, reducing the model to a single internal variable might not be a big problem.

Available parameters

The available parameters in the structure is shown below.

#![allow(unused)] fn main() { pub struct VaryingFoil { pub internal_state_data: Vec<f64>, pub foils_data: Vec<Foil>, pub current_internal_state: f64, } }

-

This is currently a hypothesis which we hope to be able to explore more in the future... ↩

Rotating cylinder

Model representing a rotating cylinder, where the main intended use case is to model rotor sails. The purpose is to calculate lift, drag on a two-dimensional cylinder as a function of how fast the cylinder is spinning.

The primary input variable to the model is the spin ratio, which is defined as the ratio of the velocity of the rotor to the wind velocity. The velocity of the rotor is defined as the circumference times the rotations per seconds.

Unlike the foil model, the rotating cylinder model is entirely data based and not parametric. There are primary two reasons for this:

- The behavior of lift and drag on a spinning cylinder is, in some ways, simpler than a foil section. The lift will generally increase with increasing spin-ratios, and not experience stall in the same way as a foil. In addition, the two-dimensional drag is generally going from a high value at zero spin-ratio to a very low value at normal operating spin-ratios. A few data points are therefore often enough to capture the behavior of a rotating cylinder.

- It is not common, at least not yet, to combine a rotating cylinder with other control mechanism. For instance, for wing sails and suction sails it is common to control the sails with both a flap angle or suction rate, and the angle of attack. A rotor sail is only controlled through its rotational speed. A simple one dimensional data model is therefore assumed to be sufficient for rotor sails (lift and drag as function of spin ratio only)

Available parameters

The parameters in the rotating cylinder are listed below.

The cl_data, cd_data and spin_ratio_data is the most important parts of the model. They specify how lift and drag is dependent on the spin ratio. All variables have default variables based on the results in the article "Calculation of Flettner rotor forces using lifting line and CFD methods". See also the validation data section for more on this.

The added_mass_factor and moment_of_inertia parameters can be used to estimate added mass forces and gyroscopic forces on the rotor. Note: more to come on these parameters later. They need further validation, and are therefore set to zero by default.

The spin ratio for each section is calculated based on the revolutions_per_second value and the local chord length and velocity. Then, the lift and drag in 2D is interpolated from the input data values.

#![allow(unused)] fn main() { pub struct RotatingCylinder { pub revolutions_per_second: f64, pub spin_ratio_data: Vec<f64>, pub cl_data: Vec<f64>, pub cd_data: Vec<f64>, pub added_mass_factor: f64, pub moment_of_inertia_2d: f64, } }

Lifting line simulations

The basics of the lifting line simulations in Stormbird have a lot in common with the classical approaches made by Lanchester (1907) and Prandtl (1918) more than 100 years ago, and which are also often taught in many introduction courses for fluid dynamics and lifting surfaces (e.g., the text books in the literature chapters). That is, the overall concept and equations is the same. The wing geometry is reduced to vortex lines along the span, the lift and circulation on the line elements are estimated from the local velocity and angle of attack based on a two-dimensional sectional model, and the lift-induced velocities due to the estimated circulation is calculated based on a potential theory wake model.

However, the Stormbird implementation also differs from the classical lifting line approach in at least three broad-stroke ways, explained further in the subsections below

Non-linear solver

In the classical lifting line method, the circulation is found by solving a simplified linearized equation system. The system is based on the assumptions that the lift-induced velocities are small and that there is a linear relationship between the lift and vertical induced velocities on the wing. As a consequence, only a single equations system must be solved for each free stream condition, which makes the solution fast and simple.

The big problem with this type of solver in the context of wind propulsion devices is that the final solution does not include viscous effects on the lift. Viscous effects are, for instance, important when wing sails or suction sails are operated close to stall. In addition, the assumption about small lift-induced velocities may not be correct for high-lift wind propulsion types, such as rotor- and suction sails.

Stormbird solves for the circulation strength in ways that attempt to capture the viscous effects in physical correct ways. That is, a stalled wing section affect both the forces and the lift-induced velocities from the wing. At the moment, there are two solvers. The first is based on the original linearized equations system, but with a post-solver empirical correction to account for viscose effects on each section. The second is a based on and iterative non-linear solver, which is mathematically more correct when the lift-induced velocities becomes large. However, with the right tuning of the model, both solvers can generally find a good solution.

More details is given in the solver chapter

Arbitrary shaped wings

The classical methods assumes that both the wing and the wake is completely flat, and that the potential theory vortex wake extends indefinitely far downstream of the wing. These are necessary assumptions to develop an analytical equation system. However, they are not necessary when solving the equations numerically.

As already explained in the line model chapter, simulation models are built up of several discrete line elements. This makes it possible to have arbitrary shaped wings, and have multiple wings together in the same simulations. To make this possible in a lifting line simulation, it is necessary with some way to calculate induced velocities from a line element. This is done by assuming that each line line element is a constant strength vortex line.

Such vortex lines are also often used in panel methods or vortex lattice methods to represent doublet panels. The exact formulation for the induced velocity as a function of line geometry and strength are taken from the VSAERO theory document

Unsteady simulations and dynamic wakes

The final extension from the classical lifting line approach is the inclusion of dynamic wakes and unsteady modeling. This means that the wings can move during a simulation, and the velocity input can change as a function of time.

Unsteady simulations comes in two flavors: 1) quasi-steady and 2) dynamic. In the quasi-steady case, the wake is as it is in a conventional lifting line simulation: It consist of horseshoe vortices that extend far downstream from the span lines of each wing for every time step. However, unsteady behavior is still modeled by changes in the felt velocity at the line elements due to the motion of the wings or changes in the freestream input.

In the dynamic case, the wake modeled is extended to consist of many doublet panels, similar to how it would be in an unsteady panel- or vortex lattice method. Both the strength and the shape of the wake panels will vary as a function of time, which allows for proper dynamic modeling of the lift. That is, the lift-induced velocities depend not only on the current state of the line model, but also the history of previous states.

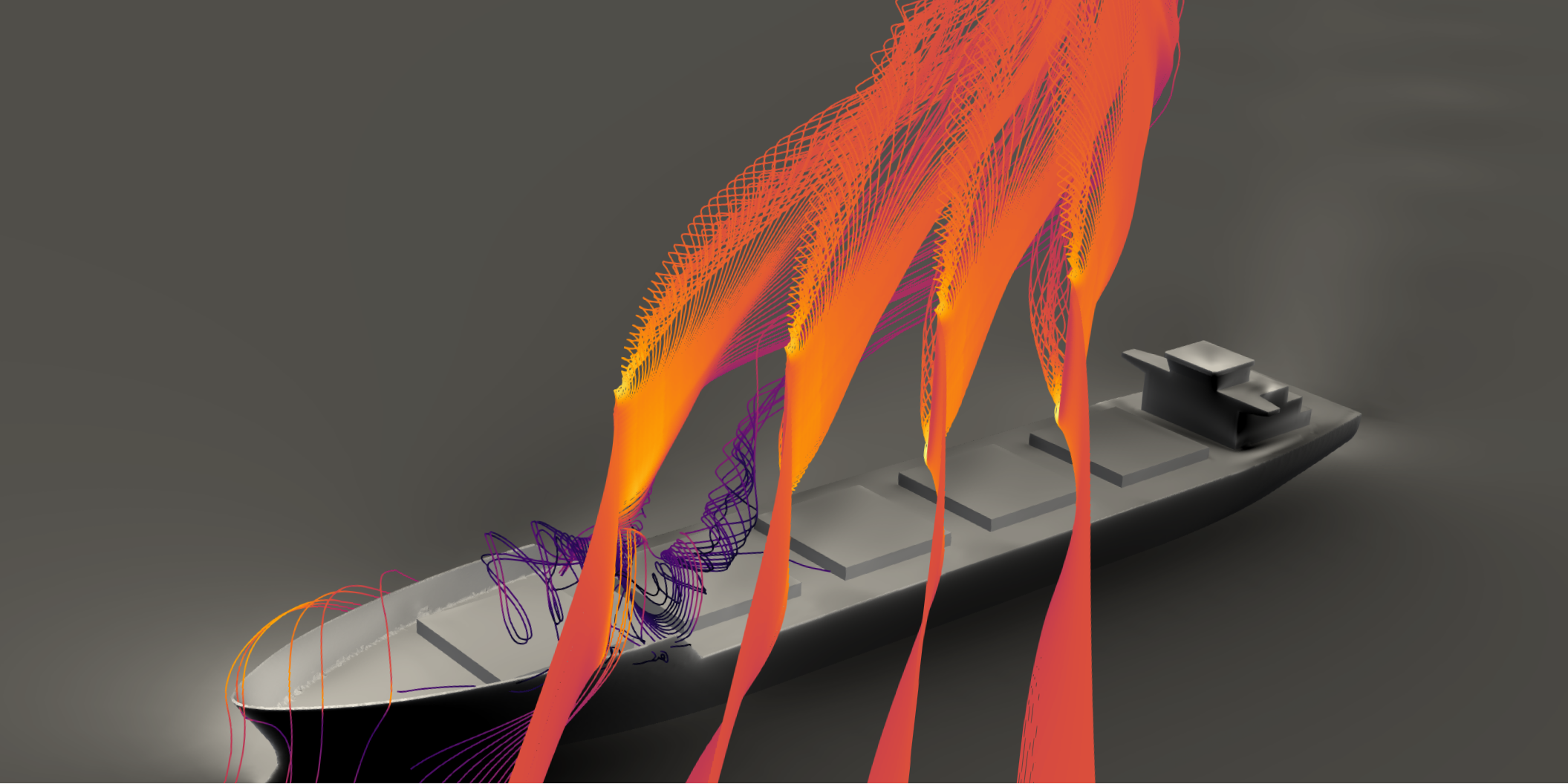

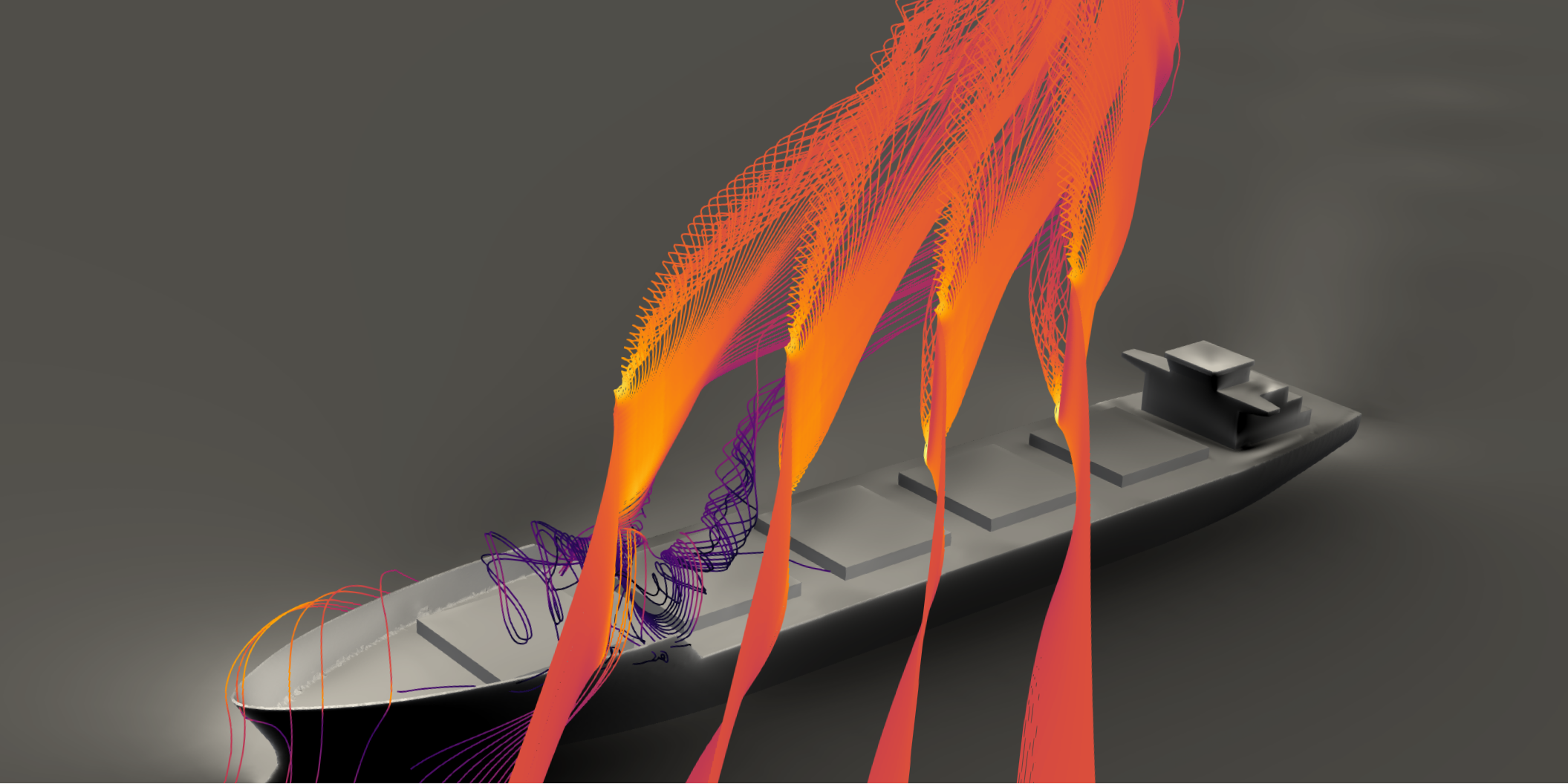

For a single conventional wing, the shape of the vortex wake is typically not that important, which is why is often assumed to be flat in simplified methods. However, we have found that this is not necessarily the case when the lift coefficient becomes very high - such as for rotor sails - or when several sails are placed so close together at the wakes get strongly deformed by other wings. When running dynamic simulations, the shape of the wake can be modified by the induced velocities in the simulation1. This can also be used to simulate steady cases where a detailed wake shape is of interest.

References

- Lanchester, F. W., 1907. Aerodynamics: Constituting the First Volume of a Complete Work on Aerial Flight

- Prandtl, L., 1918. Tragflügeltheorie. Königliche Gesellschaft der Wissenschaften zu Göttingen.

-

It is also possible to turn this of to increase the computational speed. See the wake builders section for more ↩

Simulation overview

Lifting line simulations in Stormbird are managed and executed through a specialized Simulation structure. The responsibility of this structure is to store and update the data necessary for a simulation. It can be executed once, for steady-state conditions, or for many time steps, in dynamic conditions. When executed many times, the results from the previous time steps are used as initial conditions for the next time steps.

Creating a simulation

To construct a Simulation, a SimulationBuilder is used. An overview of the fields in the builder is shown below:

#![allow(unused)] fn main() { pub struct SimulationBuilder { pub line_force_model: LineForceModelBuilder, pub simulation_settings: SimulationSettings, } }

The only input that is absolutely necessary to specify is the builder for a line force model. The simulation settings structure have default variables.

Simulations in Python are created through a Simulation class that takes a JSON string containing the data for the SimulationBuilder.

from pystormbird.lifting_line import Simulation

import json

# Some code to generate setup string before this for both the line force model

# and the simulation settings.

setup_dict = {

"line_force_model": line_force_model_dict,

"simulation_settings": simulation_settings_dict

}

simulation = Simulation(

setup_string = json.dumps(setup_dict)

)

Simulation settings

The simulation settings is an Enum that specifies whether the simulation should be executed using the quasi-steady or the dynamic variant of the lifting line. Each variant includes its own settings, which gives the necessary input to each method. The point of collecting both methods into the same structure is to generate an interface where the same line force model can easily be executed in the same way using both methods. This is, for instance useful for comparison cases.

The Enum looks like this:

#![allow(unused)] fn main() { pub enum SimulationSettings { QuasiSteady(QuasiSteadySettings), Dynamic(DynamicSettings), } }

Both the QuasiSteadySettings and the DynamicSettings have the same general fields: one structure for the solver and another for the wake. The actual rust definition looks like this:

#![allow(unused)] fn main() { pub struct QuasiSteadySettings { pub solver: QuasiSteadySolverBuilder, pub wake: QuasiSteadyWakeSettings, } pub struct DynamicSettings { pub solver: Solver, pub wake: DynamicWakeBuilder, } }

Running a simulation

Executing a simulation after a Simulation structure is made is done with a function called do_step. On the Rust side, it has the following signature:

#![allow(unused)] fn main() { pub fn do_step( &mut self, time: f64, time_step: f64, freestream_velocity: &[SpatialVector] ) -> SimulationResult }

The input is the current time, time step, and an a vector containing the freestream velocity at all relevant points for the model. See the velocity input section for more on how this vector is defined and how to generate it.

On the Python side, the same function looks like this 1:

def do_step(

self,

*,

time: float,

time_step: float,

freestream_velocity: list[list[float]],

) -> SimulationResult

That is, the python code takes in the same input as the Rust side, but with the equivalent Python data structures. The SpatialVector input is actually just a wrapper around an array with three elements, representing the velocity components in x, y, and z orientation. On the Python side, one can pass in a list with many three-elements sub-lists that will be converted to SpatialVectors inside the Python wrapper function before being passed to the Rust code.

If the simulation is executed using the quasi-steady approach, the time step will not generally affect the results 2. That means that a steady simulation can be executed by running a quasi-steady simulation only once.

The return from each time step is a SimulationResult. This structure has a Python implementation as well, with some minor helper methods to interpret the results.

-

The actual implementation is actually written slightly different as it is written in Rust and uses PyO3 to generate the Python interface. However, the code shown represents how it would have look like if it were written as Python code directly. ↩

-

This is only true for the first time step. It will never affect the circulatory lift, but it may add forces from added mass effects and dynamic rotation effects on the foil, if these effects are turned on. They are not turned on by default, though. In addition, these effects are always turned off for the first time step, as no motion history is available. That is, the acceleration and translation and rotation velocity is always assumed to be zero at the first time step. ↩

Solver

The job of the lifting line solver is to find the right circulation strength on the wing for the given state, i.e., the freestream velocity and the motion at the current time step. The challenge lies in the dependency between the circulation strength and the induced velocities. Changing the strength also changes the lift-induced velocities from the the potential theory wake, which means that the strength must be solved for, not just calculated.

To solvers currently exists: a linearized solver with viscous corrections and a full non-linear solver based on dampened iterations.

Linearized solver with a simple viscous correction

The linearized solver creates an equation system like the original lifting line method. The lift-induced velocities are assumed to only affect the angle of attack and the lift as a function of angle of attack is assumed to be linear. More in depth explanations may be found in text books like Anderson (2005).

The result of applying the normal lifting line assumptions is a linear equation system that can be solved using a conventional linear algebra solver. The linearized solver therefore works by first setting up the equation system as a matrix and a right-hand side vector, before solving it using conventional Gaussian elimination.

However, the procedure above is only the first step. Due to the assumption of linear lift as a function of angle of attack, the resulting circulation that is returned from the solver is without any stall- or other non-linear effects on the lift. To account for this, a simplified viscous correction methods is applied after solving for the circulation strength using a linear solver. It consists of the following steps:

- Calculate the lift-induced velocities and resulting effective angle of attack with the solved circulation strength

- Calculate the lift both with a linearized sectional model and the full sectional model, including stall effects

- Correct the solved circulation strength by multiplying it with the full lift and dividing it by the linearized lift

- Recalculate lift-induced velocities and effective angles of attack for the final force calculations

This solver is found to work fine for quasi-steady cases, but do also tend to predict stall at a larger angle of attack than the full non-linear solver below. However, the stall-issue can be handled by tuning the stall behavior of the sectional model to 3D data of a single sail. For quasi-steady cases it will be significantly faster than running the full non-linear solver described in the next section, and is therefore set to the default solver for such cases.

Non-linear solver using damped iterations

The second solver is inspired by a simple approach outlined in Anderson (2005), chapter 5.4. The basic principle is to start with a first guess of the circulation distribution and then slowly update the values based on iterative calculations of the lift-induced velocities. In short, for every iteration of a lifting line solver, the following is calculated:

- The lift-induced velocities from the wake model, where the circulation strength from the last iteration (or initial guess, if it is the first iteration) is used as input to the wake model.